FACTORY DIRECT SHIPPING. PRECISION METRIC GEARS. WORLD-CLASS MANUFACTURING.

Our Factory Direct Shipping enables all KHK stock gears to be delivered to any customer located anywhere within the USA, within 3 business days.*

Free Gear Calculation Software

What is a Metric Gear?

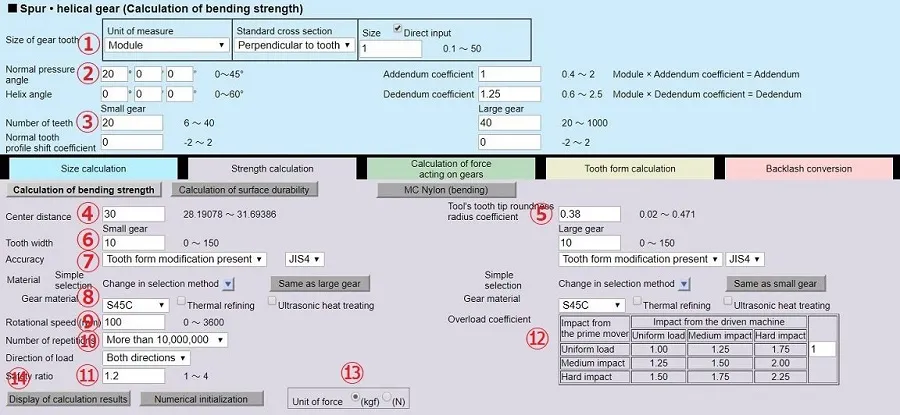

Access the FREE Gear Calculation Software and FREE Gear Drafting Software programs created by Kohara Gear Industry (KHK). With a few known parameters, these programs will help you design the best gear geometry for your unique application. Please contact us at 516-248-3850, to discuss the production of your design.

Traditionally metric means a measurement method based on meter, but when used in sentences as metric gears, it means the sizes of gears are based on the pitch (size) in the unit called module (m). When the unit of Module is used, the pitch can be computed as the multiple of π. For example, if the module is 2, the pitch is 6.2832mm, and if the module is 3, the pitch is 9.4248mm. The module is set to be the unit to indicate the pitch of the gear teeth by ISO, but there are other units such as DP (diametral pitch). Also, while Module is internationally widely used, DP is still heavily used in the US, but DP can be approximated to Module by the formula, Module= 25.4/DP.

As mentioned before, gears using Module as the unit of Pitch are called Metric Gears, conversely, gears using DP as the unit of Pitch are called Imperial Gears. The major difference between metric and imperial gearing is in length units, however, while tools such as hobs and shafts, etc. differ in sizes, production processes such as teeth cutting and grinding, manufacturing equipment such as hobbing machines and AISI and SAE specified materials do not fundamentally differ between the two. While the majority of gear manufacturers in the US make Imperial Gears, KHK's focus is on producing world-class quality metric gearing as its main product offering.

Free Gear Calculation Software

Access the FREE Gear Calculation Software and FREE Gear Drafting Software programs created by Kohara Gear Industry (KHK). With a few known parameters, these programs will help you design the best gear geometry for your unique application. Please contact us at 516-248-3850, to discuss the production of your design.